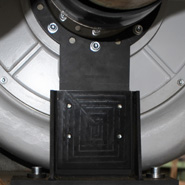

Impellers and housings are subject to strong wear and tear by tobacco dust particles. Standard impellers can be worn out after 1.500 hours only. The improved TMQS impeller provides a significantly longer service, thus giving a fast return of investment of the conversion cost. In addition, measurable noise reduction is achieved. The conversion kit blower consists of a pre-assembled cast iron blower including adaption material and an improved impeller wheel which replaces the old aluminium blower. It also includes an additional support for any VE 70 / 80 / 90 (with small hopper and existing foot). Wear and heat development are reduced to a very large extent.

Impellers and housings are subject to strong wear and tear by tobacco dust particles. Standard impellers can be worn out after 1.500 hours only. The improved TMQS impeller provides a significantly longer service, thus giving a fast return of investment of the conversion cost. In addition, measurable noise reduction is achieved. The conversion kit blower consists of a pre-assembled cast iron blower including adaption material and an improved impeller wheel which replaces the old aluminium blower. It also includes an additional support for any VE 70 / 80 / 90 (with small hopper and existing foot). Wear and heat development are reduced to a very large extent.Advantages

- Fast return on investment

- Optimized operational security

- Enhanced wear resistance and long service intervals

- Reduced storage costs. Universal application in various machine types

- Noise reduction compared to standard blower