#Filtermaking #AF-Rollers #NBR_PU #ServiceLife

The first edition of the TMQS Newsletter 2026 focuses on filter makers, with particular attention to AF rubber rollers. From early-generation AF1 machines to modern filter rod-making solutions such as KDF6, the primary function of rubber rollers – working together with the metallic thread rollers – is to prepare the acetate tow for feeding into the KDF rod maker and to form filter rods that meet the required product specifications.

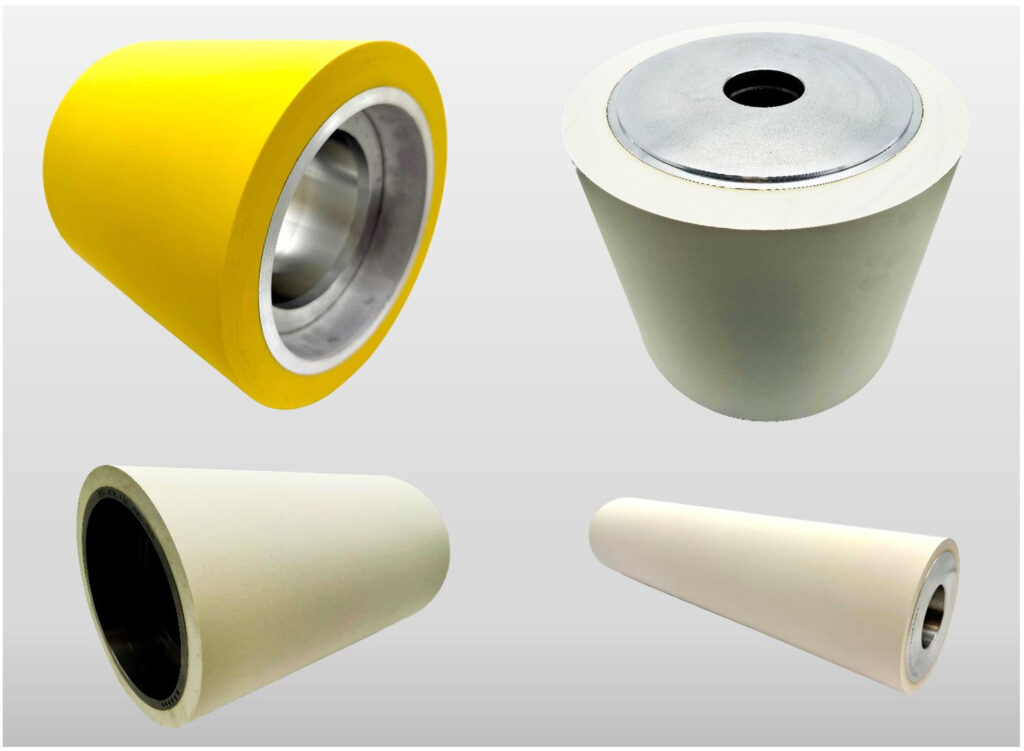

TMQS offers a comprehensive range of AF rubber rollers, ensuring compatibility across multiple generations of filter makers—from older series to the latest models.

The newer PU AF rollers deliver improved physical performance and significantly longer service life compared to traditional NBR rollers. The main advantages of the PU material are the following:

- Reduced surface wear, lower abrasion from acetate tow (hardness up to 90-95 Shore A)

- Less prone to swelling, softening and chemical attack from triacetin and similar additives

- Maintains constant diameter and surface quality → more consistent acetate transport and preparation

- Good resistance to oils, greases, plasticizes, and solvents used in acetate processing

- Better performance under higher nip pressures

TMQS has also corresponding metallic thread rollers in portfolio. Just provide us your request.

Benefits

- Advanced Technology: Utilizing durable, high-quality materials for enhanced performance and longevity.

- Full Compatibility: TMQS solutions seamlessly integrate with OEM filter making machines, ensuring smooth operation without hassle.

- Variety of rollers: Supporting all common rollers diameters, materials and ranges acetate processing threads.

- Cost Efficiency: Achieving significant cost savings while maintaining competitive pricing for optimal value.

- Supplier Independence: Reducing reliance on a single supplier, allowing for more flexibility in sourcing and procurement.

- Comprehensive Support: Offering complete assistance, from sub-assemblies to individual spare parts, ensuring you have everything you need for uninterrupted production.

To receive a quote for your specifically required model or version, just contact out TMQS sales contact or send an email to sales@tmqs.de .

We are looking forward to your enquiry.